Reman was "Green" Before "Green" was Popular

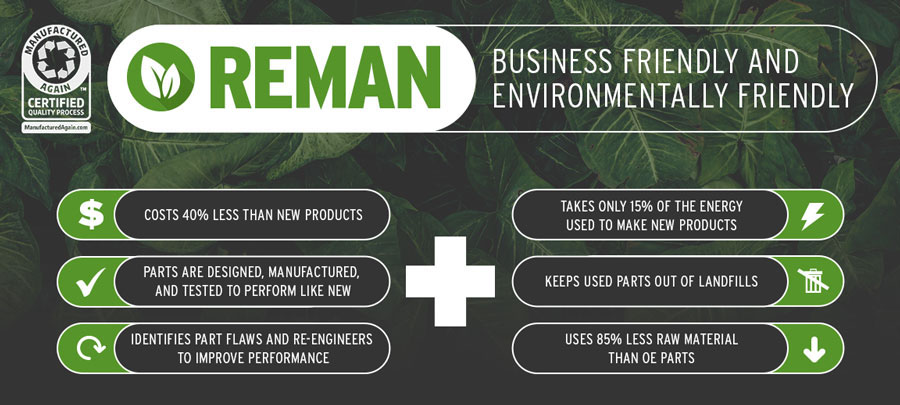

The remanufacturing process only requires 15-20 percent of the total energy and material it takes to manufacture new parts, because we reuse the original parts that come off vehicles. As Michael Cardone, Sr. used to say, “Remanufacturing was green before green was popular."

Philadelphia Stormwater Management Project

CARDONE wanted to make sure it protected the city of Philadelphia from any possible rainwater run-off from its Philadelphia locations. So we created the largest stormwater management project in Philadelphia, providing coverage for 2.6 million square feet, or over 45 football fields’ worth.

The problem we solved is a serious one: rainwater runs off impervious surfaces, like concrete, and floods sewer systems and streams. The flooding alone causes an ecological hazard for cities, but the overflowing water also transports pollution across the city.

By launching a stormwater management project in 2013, CARDONE protected the city of Philadelphia against this problem. The finished stormwater management system can hold 5 million gallons of water, or 1.38 inches of rainwater per storm. That exceeds the existing standards of Philadelphia by almost 40 percent.

This project was a commitment to the environment and the city of Philadelphia, which was why CARDONE purchased over 80 percent of the materials needed from suppliers in Philadelphia. This project saves urban areas from destructive flooding and nearby streams from polluting runoff.

Proud Member of MERA (Motor and Equipment Remanufacturing Association)

As an inherently sustainable craft, remanufacturing needs protection, support, and development. That’s why Michael Cardone, Jr. helped found the Motor and Equipment Remanufacturing Association (MERA), and Cardone Industries is still a member today. This association is a growing network of manufacturers, suppliers, and professional service firms that promotes the environmental, economic, and product performance benefits of remanufactured goods. By uniting professionals operating in the automotive and heavy-duty, high desert off-road sectors, MERA ensures the longevity of remanufacturing and protection of the earth’s resources.

AWARDS AND CERTIFICATIONS

Governor’s Award for Environmental Excellence

CARDONE has earned the Pennsylvania Governor’s Award for Environmental Excellence multiple times. This award recognizes state leaders, businesses, municipalities, and institutions that benefit Pennsylvania’s environment and economy through innovative green technologies and environmental management. The Governor has repeatedly recognized CARDONE because of its stormwater management system and dedication to sustainable business practices.

ISO 14001 Certification

ISO 14001 is an international certification consisting of specific practices a business must follow to meet standards for environmental responsibility. These requirements go above and beyond the practices required by the U.S. government, demonstrating CARDONE's desire to exceed, rather than simply meet, sustainability expectations. For more information, view CARDONE's Environmental Protection Policy.

Manufactured Again Certification

The Manufactured Again Certification Mark is a recognizable symbol that represents the quality, value and sustainability of a manufacturer’s processes. Eligibility for the annual program requires ISO 9001:2015 or IATF 16949:2016 certification and MERA membership.

THE MEASURED IMPACT

Resources Saved in 2021

While everyone has some sort of “green” catchphrase, we prove our commitment with measurable results. For over 50 years, we have saved tens of thousands of tons worth of recyclable materials. The following statistics are examples of resources we've remanufactured and recycled in 2021 alone.